Delving Beneath the Surface: Uncovering Our Founder's Pursuit of Greener Packaging

The nursery industry has long been a big user of single-use plastics. Plants in a Box have always done our best to minimise our carbon footprint. For years our fabulously fearless founder, Elle Prince, has been working on refining our packaging so that we can eliminate as much plastic and non-recyclable material as possible, so we can hand down better packaging to the next-gen and puff out our chests about our plant mail, just that little bit more.

Our goal has always been to create good looking packaging that is both eco-friendly and sustainable to ensure more eco-conscious transactions for our customers. After years, and boy do we mean years, of enquiring into different alternatives, we finally found a solution, and we wanted to share our journey with you!

1. The discovery: (Not so) biodegradable plastics

Our founder's journey began with research into a popular eco staple – biodegradable plastics. While these 'eco-plastics' sounded amazing, they aren't as eco-friendly as you would think. Biodegradable plastics need to be heated at a high enough temperature to break down properly. They can't be effectively composted or anaerobically digested and don't usually break down in landfills. In the oceans, the water is generally too cold to break down biodegradable plastics, so they either float forever on the surface (just like conventional plastics) or, if they do break down, produce tiny plastic fragments that are harmful to marine life. In other words, they are not as great as they sound... Humph.

But here's the catch! Only 25% of Australians own a compost bin, and most council areas don't even offer large scale composting programs for their communities. Double Humph!

"All of those 'biodegradable' bags and plastics aren't, in fact, biodegrading, and many people think terms like "bioplastic," "biodegradable," and "compostable" mean the same thing. But there's a huge difference. Confusing jargon hinders public understanding, which makes it harder for consumers to grasp the issues and make positive choices when they shop."

"It was such a depressing realisation, but I didn’t want to give up! I used this info and my stubborn nature to further ignite my mission to find a truly sustainable alternative,” Elle said.

2. Planning our journey: Our packaging prerequisites

Before setting out on our sustainable packaging journey, we needed to establish our key requirements. We needed our packaging to:

-

Present well to our wonderful customers

-

Allow safe and secure delivery of our plants with none, or limited soil spillage

-

Fit around our different sized tubes (what we grow our plants in)

-

Hold moisture to ensure our plants can survive up to two weeks in transit

-

Fit around a huge range of different plant stems (from trees to groundcovers)

-

Remain cost-effective, so our customers don't pay extra for sustainable packaging

-

Be fast and easy to use, so packing didn't become a time sink for our plant nerds

-

Be fully earth compostable to be torn up and thrown into the garden for a second life.

-

Elle's current mind state = Was this even doable?

3. A long journey: The challenges of small-scale sustainable packaging

Elle spent two years inquiring into different sustainable packaging alternatives. She reached out to loads of packaging suppliers but suffered a lot of knock-backs. As a smaller business, we couldn't buy packaging in their usual high volumes.

"Order volumes are a real barrier to entry for smaller businesses trying to do better. It made me realise we needed to switch our mindset from 'will the customer pay for this add on?' to 'we need to give back and make the world a better place, even if it costs us'", Elle revealed.

Over the years, Elle trialled endless materials. She investigated food packaging options, cassava bags, biodegradable bags and learned about the impact of each of these materials.

"Cassava bags seemed like a fantastic option, but while they're fully compostable, they're not sustainable - as cassava serves as a major food group for some communities. We investigated seaweed, mushroom and starch-based materials, but there was nothing that would fit the bill – nothing that would hit all our targets".

4. The home straight: Design and collaboration

While the right material eluded her, Elle came up with an initial design for our sustainable packaging, inspired by clam-shell-like food containers and many nights out at Guzman and Gomez.

We sketched up a design and 3D version of our ideal design, not knowing yet what it would be made of. We then took this design and emailed countless sustainable packaging suppliers. Literally hundreds of companies across Australia and the rest of the world. "This was at peak covid too, so progress was slow," Elle explained.

"Eventually, I woke to an email from a small Sydney-based startup called Roo Create, who promoted moulds made of a sugarcane material, and gave us the positive response we were looking for."

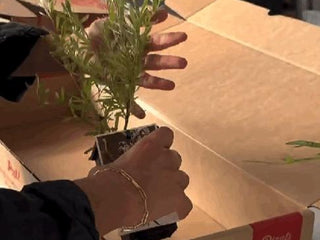

"Suzanne from Roo Create gave us our first, 'Hello, yes I think I can help you!' out of dozens of nos. From there, it was lots of back and forth, zoom meetings, trials, testings, and samples. After lots of considerations and changes to our business model to accommodate our new packaging goals, we finally created an end product that we are proud of."

4. Journey’s end: Finding bagasse

So, you probably want to know more about this wondrous material that we decided to use in our sustainable packaging, right? Well, it's called Bagasse! Bagasse (pronounced ba-GAS) is the dry pulpy fibrous material that remains after processing sugarcane to extract the sugar.

It's a natural by-product of sugarcane and can be used as biofuel for producing heat, energy and electricity, as pulp and building materials, and as a replacement for foam or paper products.

"Bagasse packaging is one of the best and most eco-friendly options out there. Not only is Bagasse packaging better for the environment due to its biodegradable and compostable nature, but it's also aesthetically pleasing," Elle detailed.

5. The road ahead: A plant nerd’s job is never done

If this journey has taught us anything, it's that sustainability is difficult to achieve. Our sustainable packaging endeavours were never perfect, but in the end, trying something is better than doing nothing. Despite all the setbacks and tears we didn't give up!

"We know our customers are as invested as we are, and it's a real 'feel good thing' for us, and our customers, to be able to send and receive nature without the footprint," Elle shared.

This is not the end of our journey. We realise we haven't achieved perfection, but we will keep tweaking and looking to do better.

"The nursery industry is traditionally quite single-use in terms of their plastic consumption. They are trying to do better, but it's slow-growing. We're excited to be able to lead the way a little."

6. Tell us what you think!

We are so proud of our new packaging design and are so excited to finally be shipping out trials to you. As always, we welcome customer feedback and are excited to see what you think of our new and improved sustainable packaging!